| ||

| Figure 1 Demonstration model DSG transmission with programmable control. |

The Volkswagen/Audi DSG Transmission

Early in 2003, Volkswagen introduced a new kind of automatic gearbox as fitted to the Golf RS32. This DCT (Dual Clutch Transmission), known as DSG (Direct Shift Gearbox), was also made available in the Audi 3.2 TT Quattro, who named the DSG "S-Tronic".Since then, the DSG has become optional equipment on most VW cars and is manufactured in the Kassal transmission plant which is capable of producing 1000 transmissions per day.

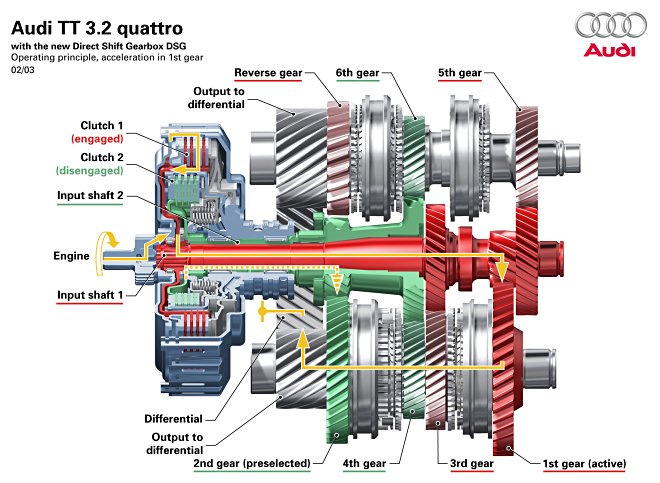

The DSG is a kind of automated manual gearbox in that it uses the Borg Warner DualTronic wet-clutch and control system technology in conjunction with a new configuration of VW standard gear and synchromesh mechanisms.It is a six-speed and reverse arrangement, effectively two gearboxes in one. It uses two clutches, one (C1) serving the odd numbered gear ratios, driving an input shaft to the 1st, 3rd, 5th and reverse synchronizers, and the other (C2) serving the even numbered gear ratios, driving the input shaft to the 2nd, 4th and 6th speed synchronizers. The odd and even geared shafts then drive a common differential gear. Figure 2 is a cut-away of the whole transmission.

| ||

| Figure 2 DSG Transmission as fitted to the Audi TT 3.2 V6 Quattro, 4WD version. Viewed from the front of car. |

Drive to the rear axle is taken from the output at the left hand side, to a rear axle mounted Haldex clutch

The principle of operation is that whilst an odd numbered gear ratio is being driven by one clutch (C1), an even numbered gear ratio can be pre-selected, ready for engagement by switching to the second clutch (C2). This action repeats for even to odd gear changes and hence for all upshifts and downshifts.

The result is virtually continuous power flow during gearshifts that are quicker than a manual gearbox and smoother than a conventional automatic transmission.

Typical shift times are 0.3 to 0.4 seconds; during upshifts engine power is interrupted for only 8 milliseconds. Shift quality is ensured by the modulated transfer of torque from clutch to clutch, since in multi-plate wet clutches, better control of friction and wear is possible, and heat energy is dissipated by the circulating cooling fluid. This is unlike dry clutches, which consume their friction material and require eventual replacement.

The DSG arrangement is also more efficient than the conventional hydrodynamic torque converter equipped automatic transmission (a torque converter has a peak efficiency of 86-90% at a pre-determined speed ratio, at all other speed ratios the efficiency falls to zero at stall and run-out).

| ||||

| Figure 3 DSG gear/clutch schematic and 1st and 2nd gear drive-paths. |

History

The beauty and simplicity of the DSG principle is not new, however. The invention of the double clutch gearbox is attributed to a French engineer, Andolphe Kegresse, around 1939 (figure 5). He intended to use it in the Citroen "Traction" vehicle, but business and war circumstances prevented further development.

|

| Figure 4 Kegresse dual clutch gearbox proposal. |

Years later, Automotive Products (AP) proposed a double clutch/gearbox of different design (figure 6). In 1985 Porsche raced a similar gearbox to Kegresse known as PDK (Porsche Dual Klutch), a 5-speed unit with dry plate clutches (figures 7 and 8), whilst Luk/Devotek proposed the PSG (Parallel Shift Gearbox) using wet or dry clutches (figure 9).

|

| Figure 5 AP schematic for 4 and 6 speed designs |

|

| Figure 6 Porsche-Audi PDKcaption. |

|

| Figure 7 Porche-Audi PDK schematic. |

| ||||||||

| Figure 8 Luk/Devotek PSG twin dry plate clutch. |

No comments:

Post a Comment