|

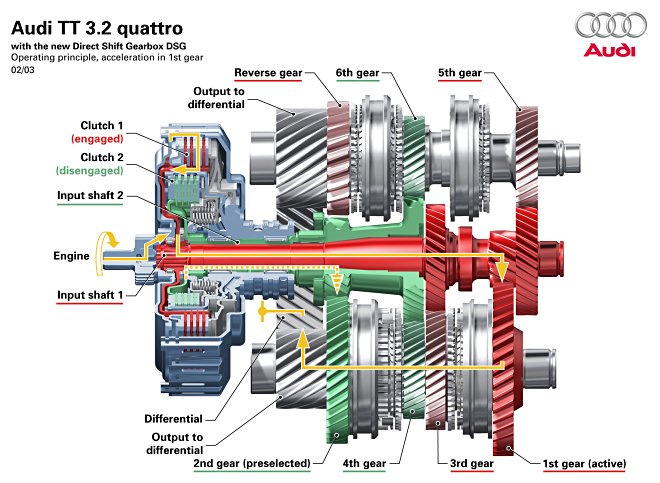

| Picture 1.1 : DSG Gearbox Overview |

|

The Direct-Shift Gearbox , commonly abbreviated to DSG is an electronically controlled dual clutch multiple-shaft manual gearbox, in a transaxle design without a conventional clutch pedal, and with full automatic, or semi-manual control. The first actual Dual Clutch transmissions derived from Porsche in-house development for 962 racing cars in the 1980s.

In simple terms, it is two separate manual gearboxes (and clutches), contained within one housing, and working as one unit. It was designed by BorgWarner, and was initially licensed to the German automotive industry concern Volkswagen Group (which includes the Volkswagen Passenger Cars, Audi, SEAT, Škoda, Lamborghini, Bentley, Bugatti, Porsche, and Volkswagen Commercial Vehicles automotive marques),by using two independent clutches, a DSG can achieve faster shift times, and eliminates the torque converter of a conventional epicyclic automatic transmission.

Transverse DSG.

At the time of launch in 2003 - it became the world's first dual clutch transmission in a series production car, in the German-market Volkswagen Golf Mk4 R32 and shortly afterwards, worldwide in the original Audi TT 3.2; and for the first few years of production, this original DSG transmission was only available in transversely orientated front-engine, front-wheel-drive — or Haldex Traction-based four-wheel-drive vehicle layouts.

The first DSG transaxle that went into production for the Volkswagen Group mainstream marques had six forward speeds (and one reverse), and used wet/submerged multi-plate clutch packs (Volkswagen Group internal code: DQ250, parts code prefix: 02E). It has been paired to engines with up to 350 N•m (260 lb•ft) of torque, and the two-wheel-drive version weighs 93 kg (210 lb). It is manufactured at Volkswagen Group's Kassel plant, with a daily production output of 1,500 units.

Operational Introduction.

The internal combustion engine drives two clutch packs. The outer clutch pack drives gears 1, 3, 5 (and 7 when fitted), and reverse — the outer clutch pack has a larger diameter compared to the inner clutch, and can therefore handle greater torque loadings. The inner clutch pack drives gears 2, 4, and 6. Instead of a standard large dry single-plate clutch, each clutch pack for the six-speed DSG is a collection of four small wet interleaved clutch plates (similar to a motorcycle wet multi-plate clutch).

Due to space constraints, the two clutch assemblies are concentric, and the shafts within the gearbox are hollow and also concentric. Because the alternate clutch pack's gear-sets can be pre-selected (predictive shifts enabled via the 'unused' section of the gearbox), un-powered time while shifting is avoided because the transmission of torque is simply switched from one clutch-pack to the other.

This means that the DSG takes only about 8 milliseconds to upshift. In comparison, the sequential manual transmission (SMT) in the Ferrari F430 Scuderia takes 60 milliseconds to shift, or 150 milliseconds in the Ferrari Enzo. The quoted time for upshifts is the time the wheels are completely non-powered.

DSG controls

The Direct-Shift Gearbox utilizes a floor-mounted transmission shift lever, very similar to that of a conventional automatic transmission. The lever is operated in a straight 'fore and aft' plane (without any 'dog-leg' offset movements), and utilizes an additional button to help prevent an inadvertent selection of an inappropriate shift lever position.

"P'' Mode

P position of the floor-mounted gear shift lever means that the transmission is set in "Park". Both clutch packs are fully disengaged, all gear-sets are disengaged, and a solid mechanical transmission 'lock' is applied to the crown wheel of the DSG's internal differential. This position must only be used when the motor vehicle is stationary. Furthermore, this is the position which must be set on the shift lever before the vehicle ignition key can be removed.

"D'' Mode

Whilst the motor vehicle is stationary and in neutral (N), the driver can select D for "drive" (after first pressing the foot brake pedal). The transmission's reverse gear is selected on the first shaft k1 , and the outer clutch K2 engages at the start of the 'bite point'. At the same time, on the alternate gear shaft, the reverse gear clutch K1 is also selected (pre-selected),gearbox still doesn't know whether the customer wants to go forward or reverse (could still change even though its in d) but the clutch pack for second gear (k2) get ready to engage . When the driver releases the foot brake pedal, the k2 clutch pack increases the clamping force, allowing the second gear to take up the drive through an increase of the 'bite point', and therefore transferring the torque from the engine through the transmission to the driveshafts and roadwheels — and the vehicle moves forward. Pressing the throttle / accelerator pedal will fully engage the clutch, and causes an increase of forward vehicle speed, pressing the throttle pedal to the floor (hard acceleration) will cause the gear box to kick down to first gear to provide the acceleration associate with first although there will be a slight hesitation while the mechatronics deselects second gear and selects first gear As the vehicle accelerates, the transmission's computer determines when the second gear (which is connected to the second clutch) should be fully utilised. Depending on the vehicle speed, and amount of engine power being requested by the driver (full throttle, or part-throttle normal driving), the DSG then upshifts. During this sequence, the DSG disengages the first outer clutch whilst simultaneously engaging the second inner clutch (all power from the engine is now going through the second shaft), thus completing the shift sequence. This sequence happens in 8 milliseconds (aided by pre-selection), and can happen even with full throttle opening, and as a result, there is virtually no power loss.

"S'' Mode.

The floor selector lever also has an S position. When S is selected, "sport" mode is activated in the DSG. Sport mode still functions as a fully automatic mode, identical in operation to "D" mode, but upshifts and downshifts are made much higher up the engine rev-range. This aids a more sporty driving manner, by utilising considerably more of the available engine power, and also maximising engine braking. However, this mode does have a detrimental effect on the vehicle fuel consumption, when compared to D mode. This mode may not be ideal to use when wanting to drive in a 'sedate' manner; nor when road conditions are very slippery, due to ice, snow or torrential rain — because loss of tyre traction may be experienced (wheel spin during acceleration, and may also result in roadwheel locking during downshifts at high engine rpms under closed throttle). On 4motion or quattro-equipped vehicles this may be partially offset by the drivetrain maintaining full-time engagement of the rear differential in 'S' mode, so power distribution under loss of front-wheel traction may be marginally improved.

S is highlighted in the instrument display, and like D mode, the currently used gear ratio is also displayed as a number.

''R'' Mode

R position of the floor-mounted shift lever means that the transmission is in "reverse". This functions in a similar way to D, but there is just one 'reverse gear'. When selected, R is highlighted in the instrument display.

Manual Mode

Additionally, the floor shift lever also has another plane of operation, for manual mode, with spring-loaded "+" and "−" positions. This plane is selected by moving the stick away from the driver (in vehicles with the driver's seat on the right, the lever is pushed to the left, and in left-hand drive cars, the stick is pushed to the right) when in "D" mode only. When this plane is selected, the DSG can now be controlled like a manual gearbox, albeit only under a sequential shift pattern.

In most (VW) applications, the readout in the instrument display changes to 6 5 4 3 2 1, and just like the automatic modes, the currently used gear ratio is highlighted or emboldened. In other versions (e.g. on the Audi TT) the display shows just M followed by the gear currently selected, e.g. M1, M2 etc.

To change up a gear, the lever is pushed forward (against a spring pressure) towards the "+", and to change down, the lever is pulled rearward towards the "−". The DSG transmission can now be operated with the gear changes being (primarily) determined by the driver. This method of operation is commonly called "tiptronic". In the interests of engine preservation, when accelerating in Manual/tiptronic mode, the DSG will still automatically change up just before the redline, and when decelerating, it will change down automatically at very low revs, just before the engine idle speed (tickover). Furthermore, if the driver calls for a gear when it is not appropriate (e.g.: requesting a downshift when engine speed is near the redline) the DSG will not change to the driver's requested gear.

Current variants of the DSG will still downshift to the lowest possible gear ratio when the kick-down button is activated during full throttle whilst in manual mode. In Manual mode this kick-down is only activated by an additional button at the bottom of the accelerator pedal travel; unless this is pressed the DSG will not downshift, and will simply perform a full-throttle acceleration in whatever gear was previously being utilised.

Paddle shifters

Initially available on certain high-powered cars, and those with a "sporty" trim level — such as those using the 2.0 TFSI and 3.2/3.6 VR6 engines — steering wheel-mounted paddle shifters were available. However, these are now being offered (either as a standard inclusive fitment, or as a factory optional extra) on virtually all DSG-equipped cars, throughout all model ranges, including lesser power output applications, such as the 105 PS Volkswagen Golf Plus.

These operate in an identical manner as the floor mounted shift lever when it is placed across the gate in manual mode. The paddle shifters have two distinct advantages: the driver can safely keep both hands on the steering wheel when using the Manual/tiptronic mode; and the driver can immediately manually override either of the automatic programmes (D or S) on a temporary basis, and gain instant manual control of the DSG transmission (within the above described constraints).

If the paddle-shift activated manual override of one of the automatic modes (D or S) is utilised intermittently, the DSG transmission will "default" back to the previously selected automatic mode after a predetermined duration of inactivity of the paddles, or when the vehicle becomes stationary. Alternatively, should the driver wish to immediately revert to fully automatic control, this can be done by activating and holding the "+" paddle for at least two seconds.

Advantages and disadvantages

Advantages

- Better fuel economy (up to 15% improvement) than conventional planetary geared automatic transmission (due to lower parasitic losses from oil churning) and for some models with manual transmissions.

- No loss of torque transmission from the engine to the driving wheels during gear shifts; Short up-shift time of 8 milliseconds when shifting to a gear the alternate gear shaft has preselected.

- Smooth gear-shift operations. Consistent shift time of 600 milliseconds, regardless of throttle or operational mode.

Disadvantages

- Achieving maximum acceleration or hill climbing, while avoiding engine speeds higher than a certain limit (e.g. 3000 or 4000 RPM), is difficult since it requires avoiding triggering the kick-down-switch. Avoiding triggering the kick-down-switch requires a good feel of the throttle pedal, but use of full throttle can still be achieved with a little sensitivity as the kick-down button is only activated beyond the normal full opening of the accelerator pedal.

- Marginally worse overall mechanical efficiency compared to a conventional manual transmission, especially on wet-clutch variants (due to electronics and hydraulic systems).

- Expensive specialist transmission fluids/lubricants with dedicated additives are required, which need regular changes.

- Relatively expensive to manufacture, and therefore increases new vehicle purchase price.

- Relatively lengthy shift time when shifting to a gear ratio which the transmission ECU did not anticipate (around 1100 ms, depending on the situation).

- Torque handling capability constraints perceive a limit on after-market engine tuning modifications (though many tuners and users have now greatly exceeded the official torque limits Later variants have been fitted to more powerful cars, such as the 300bhp/350Nm VW R36 and the 272 bp/350 Nm Audi TTS.